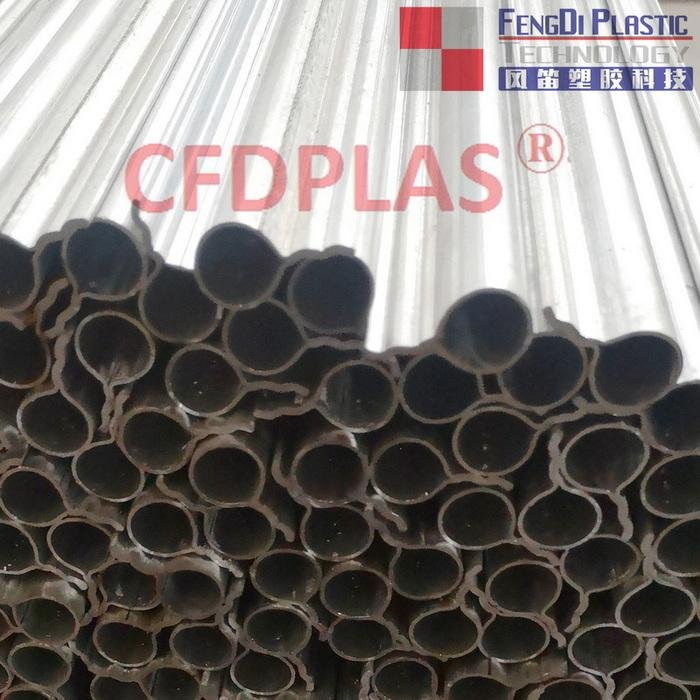

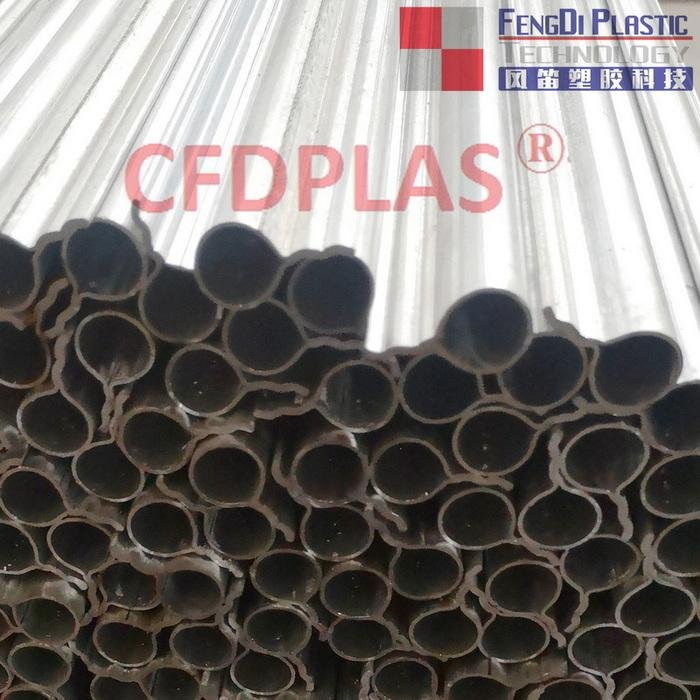

Product Description

Welded galvanized P-shaped top horizontal tubes for IBC tank frame cage

Type: modular design,P-section shaped,welded,galvanized,steel tube,top horizontal Tubes for steel cage.

Model Number:CFD-IBC-P1810P

Processing technology: cutting,bending,punching,pressing,welding,Clinching.

Color:Sliver

Material:DX51D galvanized steel sheet

Tube Section Shape: P-section shaped

Diameter of tubes:D18mm

Thickness:1.0 mm

Length of P-shaped top horizontal Tubes:usually 4175mm for IBC steel cages,Wall thickness :1.0mm;

Weight of P-shaped top horizontal Tubes:2.65 KGS.

Standard:ASTM,BS,JIS,DIN,GB,ISO

Surface Treatment:galvanized Coated,

Package:bundle package

Min. O. Q.:2000pcs,Minimum purchase requirements apply.

Application & Usage: for IBC tank steel frame cage top horizontal Tube use.

Related other welded steel tubes for IBC tank frame cages :

Length of Bottom Tubes:usually 4260mm for IBC tank bottom pallet,Wall thickness :1.4-1.5mm;

Length of embossed vertical Tubes:usually 1013mm for IBC tank steel frame cage,Wall thickness :1.0mm;

Length of crescent-shaped horizontal Tubes:usually 4230mm for IBC tank steel frame cage,Wall thickness :1.0mm;

Length of top cross bar tubes:usually 1034mm for IBC tank steel frame cage,Wall thickness :1.0mm;

General features of the welded galvanized P-section shaped steel horizontal tubes:

Modular design;

standard welded steel pipes,galvanized steel;

Optimal stacking;

Galvanized against corrosion;

Better handling for long-term use;

Limited permanent damage;

EX-compliant by integrated grounding for electrostatic load;

Composite pallet frame Stiffer for better high-rack performance;

Revolutionary crescent-section shaped steel tube frame structure support;

Easier,safer handling;

Rackable,stackable,fits perfectly into a container loading on.

Precision cutting,bending,punching and welding,pressing,Clinching for fixed strong.

Related other IBC assembly spare parts accessories:

Welded Galvanized steel pipes,galvanized steel bottom plates,welded galvanized steel tubes,

welded galvanized steel top bar(top tie rod),P-shaped galvanized steel pipes,

welded horizontal galvanized steel pipes,welded vertical galvanized steel pipes,

galvanized crescent-shaped steel tubes,embossed straight rubes,galvanized steel bottom crossbeam,

IBC bottom pallet four corner support,IBC pallet bottom mid-corner support,

marking identification label plate,discharge valves,galvanized steel tube cage,

corner protector,valve security flap,IBC top lids,IBC adapters,IBC fittings,

IBC rubber gasket(EPDM,Viton,FKM,TPE,Silicone),IBC camlock,

welded galvanized tubular steel cage,Quick disconnect valve.etc.

Related IBC steel frame cage production machine(Galvanized metal cage production cell):

IBC metallic grid mesh Welding Machine,IBC Metallic Grid Mesh Bending Machine,

IBC Metallic Grid Mesh Clinching Machine,IBC Metallic Grid Mesh Punching and Hole Making Machine,

Full Automatic Manipulator Production Line,IBC Base steel Frame Welding Machine,

Auto IBC assembly line,steel tube necking machine,crescent tube regulator,and so on.

Price Terms︰

EXW/FOB/CFR

Payment Terms︰

TT

Packing︰

Bundles Packing

Lead Time︰

in 25 days

Product Image